Oil-Based Activated Carbon: Effective Deodorizing Solution

What is oil-based activated carbon?

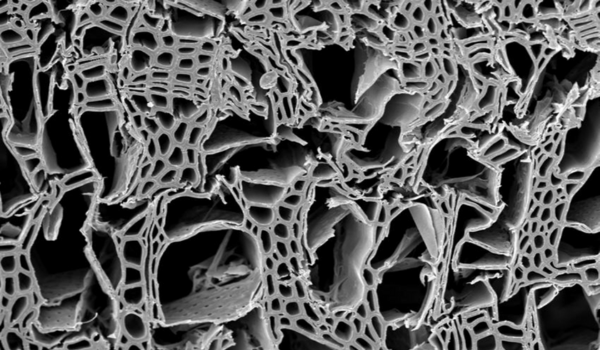

Oil-based activated carbon is produced from carbon-rich raw materials such as petroleum, coal tar or petroleum distillates. The production process involves carbonizing and activating the raw material to create a porous structure with a very large surface area.

Outstanding features of oil-based activated carbon

- Developed microporous structure: Oil-based activated carbon often has a system of small and narrow pores, creating a very large contact surface area. This enhances the ability to absorb small molecules, especially volatile organic compounds (VOCs).

- Selective adsorption capacity: Depending on the production conditions, oil-based activated carbon can be adjusted to selectively adsorb certain types of molecules, such as polar or non-polar molecules.

- High mechanical strength: Oil-based activated carbon often has higher mechanical strength than other types of activated carbon, increasing its service life and wear resistance.

The microporous structure of activated carbon has the ability to absorb volatile organic compounds (VOCs)

Advantages of using oil-based activated carbon in industrial deodorization

- High efficiency in absorbing volatile organic compounds: Oil-based activated carbon is especially effective in removing volatile organic compounds that cause unpleasant odors such as benzene, toluene, xylene, etc.

- Good deodorizing ability: Thanks to its developed porous structure and selective adsorption ability, oil-based activated carbon can effectively remove unpleasant odors in the air.

- High durability: Oil-based activated carbon can be regenerated many times by heating, helping to reduce operating costs.

Applications

- Industrial waste gas treatment: Remove volatile organic compounds, sulfur compounds, nitrogen compounds and other odorous substances in waste gas from chemical plants, metallurgical plants, paint factories, etc.

- Wastewater treatment: Remove soluble organic substances, color-causing compounds and odors in wastewater.

- Ventilation system: Deodorize in ventilation systems of buildings and factories.

- Chemical production: Act as a catalyst or adsorbent in chemical production processes.

Odor removal process with oil-based activated carbon

The odor removal process with oil-based activated carbon is similar to other types of activated carbon. However, due to the selective adsorption properties of oil-based activated carbon, it is necessary to choose the right type of carbon for each type of waste gas or wastewater to achieve the highest efficiency.

Notes when using

- Choose the right type of coal: It is necessary to choose the type of oil-based activated carbon with particle size, surface area and adsorption capacity suitable for each type of exhaust gas or wastewater.

- Operating conditions: Temperature, humidity, flow rate of gas or wastewater affect the adsorption efficiency of activated carbon.

- Regeneration: Activated carbon can be regenerated by heating at high temperature. However, the regeneration process can reduce the life of the carbon.

Conclusion

Oil-based activated carbon is an effective absorbent material, widely used in the treatment of industrial exhaust gas and wastewater. With its outstanding advantages, it plays an important role in protecting the environment and improving the quality of life.

Vina TS is a reputable unit with many years of experience in trading activated carbon in the Vietnamese market. We guarantee to bring you products with the best quality and the most optimal cost. For more information, please contact us via the following information:

Address: 82 Vu Tong Phan, An Phu Ward, Thu Duc City, Ho Chi Minh City

Hotline: 098 777 0438 (Mr. Tan)/ 0949446009 (Ms. Chau)

E-mail: vinatsinfo@gmail.com

>> Further reading: Understanding the technical specifications of activated carbon