CuSO4 Copper Plating: Process and Applications

Introduction

CuSO4 copper plating is an electrochemical process in which a layer of metallic copper is deposited on the surface of another conductive material. This process utilizes the conductivity of copper sulfate solution (CuSO4) and direct current to create a uniform and durable copper coating.

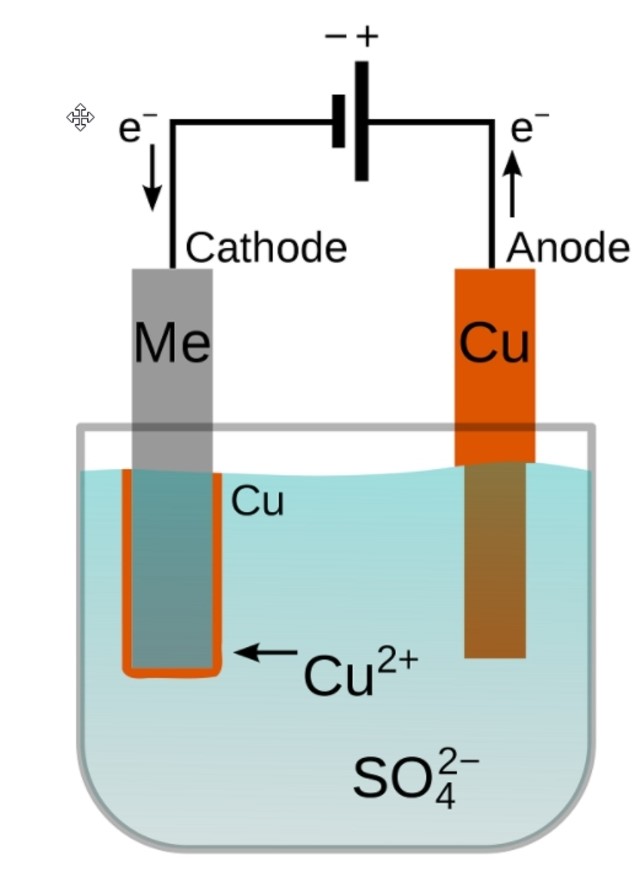

Operating principle

- Plating solution: Copper plating solution usually contains copper sulfate salt (CuSO4), sulfuric acid (H2SO4) and some other additives to improve the brightness, adhesion and uniformity of the plating layer.

- Cathode and anode: The material to be plated is connected to the negative pole (cathode) of a direct current source, while a pure copper plate is connected to the positive pole (anode).

- Electrolysis process: When the current passes through the solution, copper ions (Cu2+) move towards the cathode and receive electrons to become copper atoms attached to the surface of the material to be plated. At the same time, at the anode, copper atoms are oxidized into copper ions and enter the solution, maintaining the concentration of copper ions in the solution.

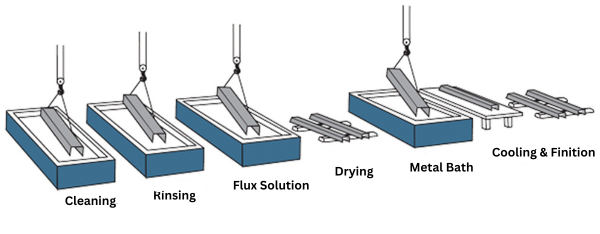

CuSO4 copper plating process

- Surface preparation: The surface of the material to be plated must be completely cleaned, removing impurities and grease to ensure good adhesion of the plating layer.

- Pretreatment: Depending on the type of material, pretreatment steps such as degreasing, rust removal, copper plating can be carried out…

- Copper plating: Immerse the material to be plated in the plating solution, connect to the power source and adjust the current and voltage appropriately to achieve the desired thickness and quality of the plating layer.

- Washing and drying: After plating, the material is washed with water to remove remaining chemicals and dried.

Applications of CuSO4 copper plating

CuSO4 copper plating has many applications in industry and life, including:

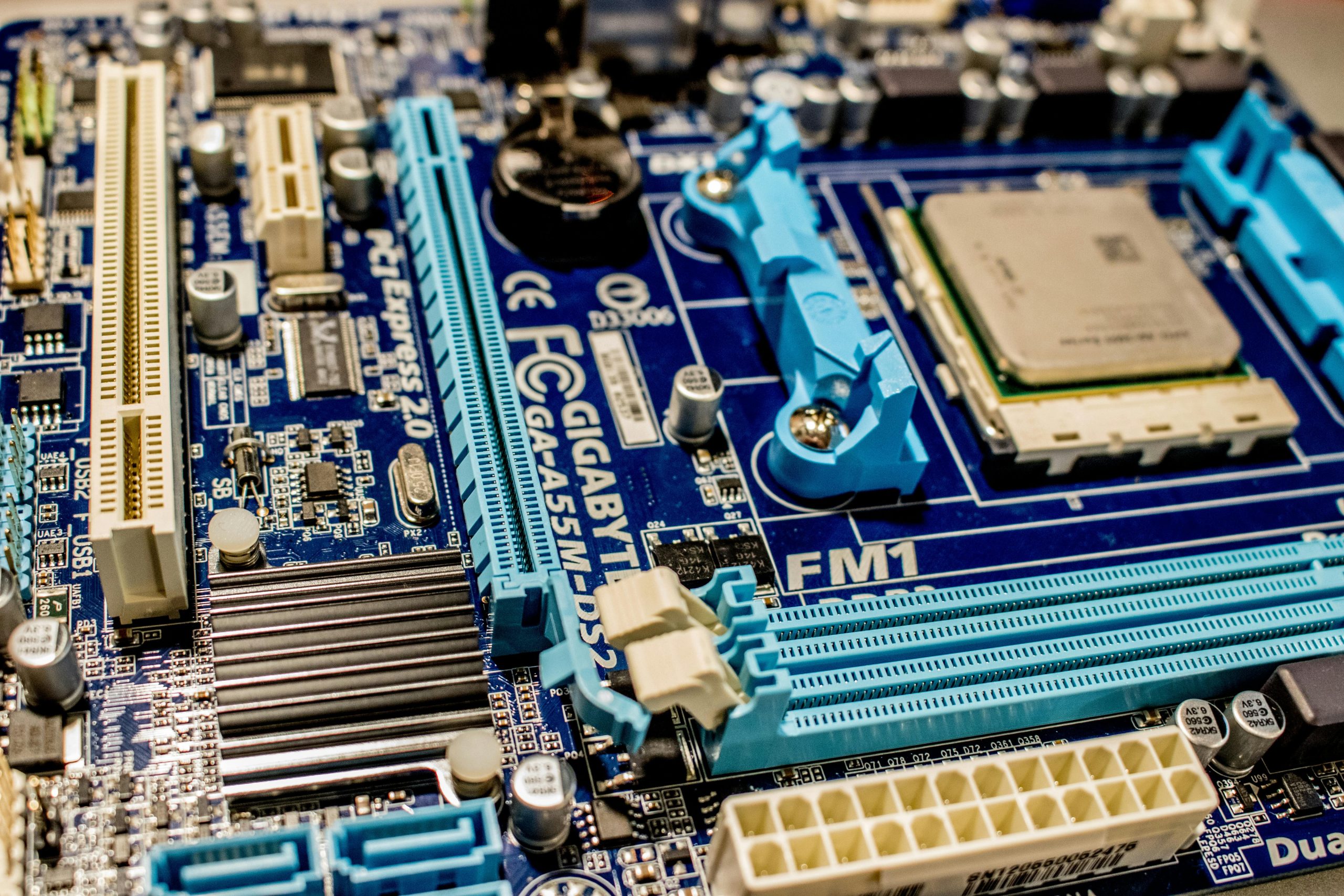

- Electronics industry: Copper plating to create a conductive layer for printed circuits and electronic components.

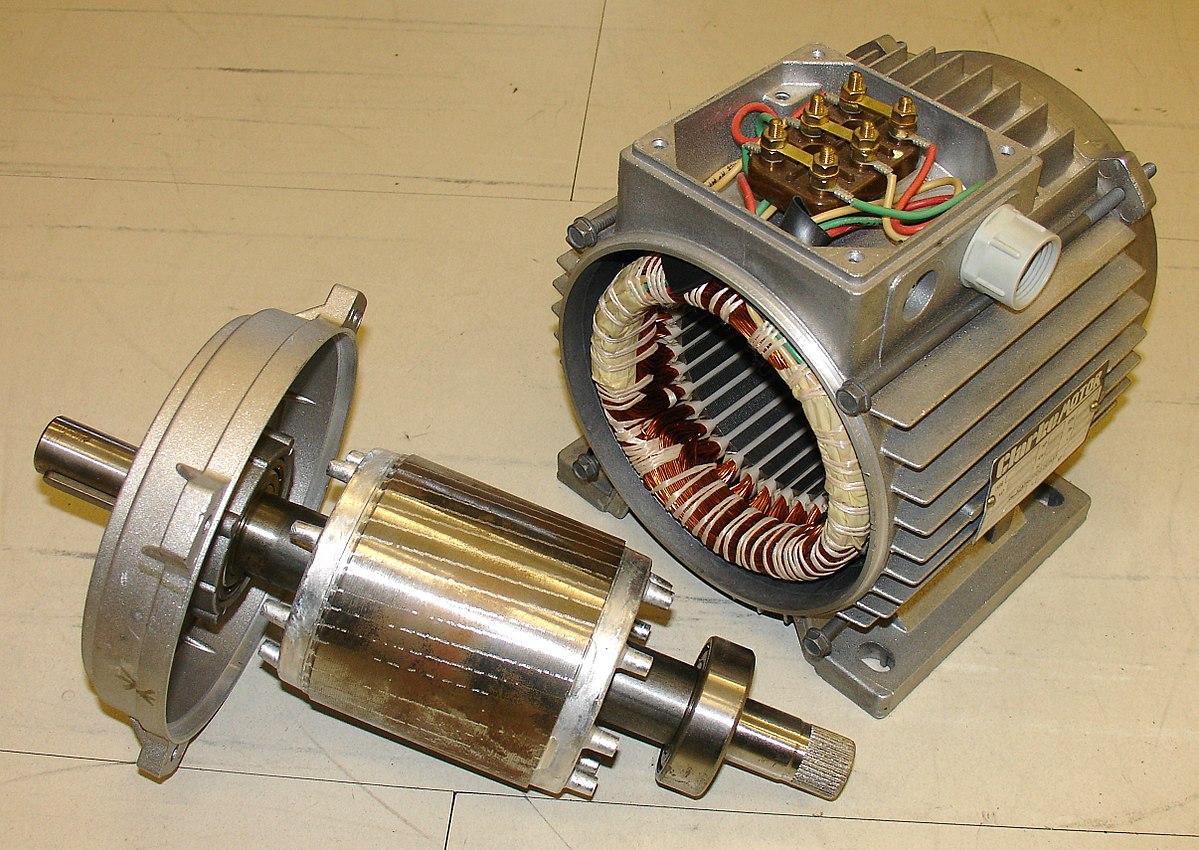

- Mechanical industry: Copper plating to increase hardness, wear resistance, and corrosion resistance for machine parts.

- Decorative industry: Copper plating to create decorative coatings for handicraft products, household appliances.

- Printing industry: Copper plating to create prints, molds.

Advantages of CuSO4 copper plating

- Good conductivity: Copper is a highly conductive metal, making it suitable for applications in the electronics industry.

- Good corrosion resistance: The copper plating layer helps protect the underlying material from environmental impacts.

- High mechanical strength: The copper plating layer increases the hardness and durability of the surface.

- Diverse applications: Copper plating can be applied to many different types of materials.

Disadvantages and solutions

- Toxicity of plating solution: Copper plating solution contains sulfuric acid which is corrosive and toxic, and chemical safety regulations must be followed.

- Cost: Copper plating requires specialized equipment and chemicals, which can be costly.

- Environmental impact: If wastewater after plating is not properly treated, it will pollute the environment.

To overcome the above disadvantages, it is necessary to use environmentally friendly chemicals, invest in modern wastewater treatment systems and comply with environmental protection regulations.

Vina TS is a company specializing in providing industrial chemicals including CuSO4. If you are looking for a source of quality CuSO4 at a good price on the market, do not hesitate to contact us using the information below:

Vina TS Company Limited

Hotline: Mr. Tan: 098 777 04 38

Phone: 028 2253 6008– 028 2253 6009

Website: https://vinats.vn/

Email: vinatsinfo@gmail.com

Address: 82 Vu Tong Phan, An Phu Ward, Thu Duc City, Ho Chi Minh City

>> Read more: How to Use Copper Sulfate for Plants: A Detailed Guide