How to treat textile wastewater using activated carbon

Activated carbon is a familiar ingredient for treating exhaust gases and wastewater in factories and enterprises. If you want to learn about how to treat textile wastewater using activated carbon, don’t miss this article!

Why use activated carbon to treat textile wastewater?

Textile wastewater contains organic residues, dissolved organic substances, nutrients, and disease-causing bacteria. If textile wastewater is not treated and discharged into the environment, it will seriously affect the water environment and cause environmental pollution.

Activated carbon can adsorb and remove dissolved substances from water. Can be used to separate heavy metals and dechlorine wastewater before entering the source. Furthermore, activated carbon is easy to use, easy to buy and low cost. Therefore, people often apply activated carbon in textile wastewater treatment.

Notes when treating textile wastewater with activated carbon

- Activated carbon quality: If the number of pores is too small or there is only a little trace, the water filtration ability will be ineffective, and the activated carbon will immediately become saturated.

- Avoid buying poor quality activated carbon, which directly affects wastewater filtration results.

- Suitable air flow: The amount of carbon or number of activated carbon levels when installed in the filter must match the air flow passing through the wastewater filtration system.

- Note the filter change cycle: Changing the filter periodically will help maximize wastewater filtration efficiency. If activated carbon is saturated, the cleaning effect is completely lost.

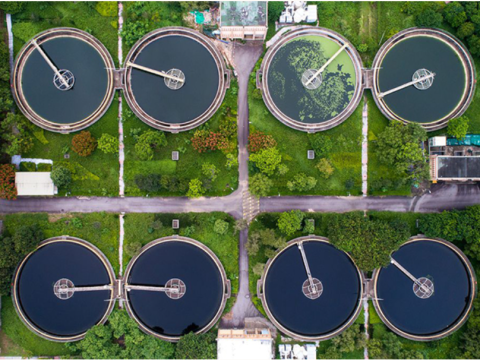

Textile wastewater treatment process with activated carbon

Wastewater treatment using biological methods

Step 1: First add PAC (contact time with wastewater about 3-5 minutes),

Step 2: Next add decolorizer (contact time 5-10 minutes),

Step 3: Then add anionic polymer.

Biological treatment followed by using chemicals to treat textile wastewater will save a lot of money if we adjust the pH to 7-8, but the amount of decolorizing agent consumed will also be higher.

Wastewater treatment by chemical methods

Factories and enterprises should adjust the pH of wastewater to about 7 – 8 before treatment for the best decolorization process. The product should be diluted 10 – 40 times then added directly to wastewater. Mix for a few minutes and let the residue in the wastewater settle and the clean water floats on top.

When color and COD content are relatively high, decolorizers are used to assist PAC but do not mix together. Processing costs in this case may be lower. Whether PAC is used before or after depends on the flocculation test and treatment process.

Pollution risk of textile wastewater

If factories and plants do not properly treat textile and dyeing wastewater, it can lead to serious consequences for the environment, flora and fauna and human health. When the water environment is polluted by toxic waste emitted from factories, it can kill aquatic organisms. People using polluted water sources can suffer from serious diseases, leading to cancer. The consequences of water pollution are extremely serious.

Above are some shares about textile wastewater treatment systems using activated carbon that readers can refer to. Wishing you more experience in the wastewater treatment process at factories/enterprises.

Where to sell quality activated carbon in the city. HCM?

Currently, there are many places selling activated carbon in Ho Chi Minh City, so it is difficult to ensure quality.

Vina TS Co., Ltd. is proud to be one of the reputable – quality – guaranteed suppliers of activated carbon in Ho Chi Minh City.

For further information, please contact us via the following information:

. Address: 82 Vu Tong Phan, An Phu Ward, City. Thu Duc, City. HCM

. Hotline: 098 777 0438 (Mr. Tan)/ 0902 092 589 (Ms. Rayna)

. E-mail address: vinatsinfo@gmail.com

. Website: www.vinats.vn

>> Further reading: What is activated cacbon? Benefits and uses in beauty